Your Industry. Our Tools. Innovative Solutions.

Explore the Widest Selection of In-Stock Deep Hole Drills!

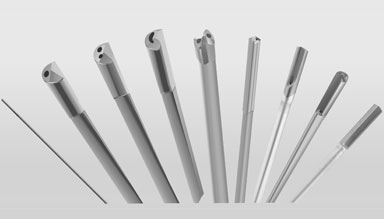

Products: Gundrills

We are the largest supplier and manufacturer of deep hole drilling tools, fixtures, and accessories in the world. We have solutions for all of your deep hole and high precision drilling needs.

Products: Rifle Barrel Tooling

We are a global leader in precision-engineered rifle tooling accessories, trusted by top firearm and barrel manufacturers worldwide for our superior-quality button rifling tools, reamers, air gages, and mandrels.

Services

We provide consulting, seminars prototype drilling as well as re-sharpening, re-tipping and re-straightening services.

Contact us today.

Tech Support

We have a dedicated staff of experts with over 85 years of combined experience to assist you with any special requirements.

Our 65,000 sq foot facility is headquartered in Milford, CT.

Our Distribution Network

High-Performance Gundrills — Built to Power Your Industry.

Precision-engineered for the most demanding applications, our deep hole Gundrills combine premium materials with advanced technology to deliver unmatched accuracy, extended tool life, and superior chip evacuation—maximizing productivity and reinforcing your competitive edge.

Aerospace

Drill Masters Eldorado Tool has been providing the Aerospace Industry with cutting edge tooling for over 50 years. Equipped with state-of-the-art machinery, we can meet the growing demands and futuristic visions of our customers. Our drills are used in aircraft engines, affix fuselage components, helicopter and space components.

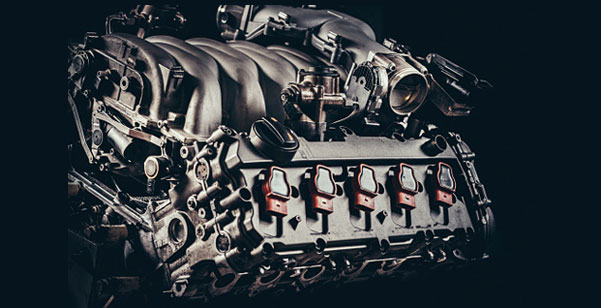

Automotive

We are highly specialized in providing deep hole drills for the Automotive Industry. We specialize in drills for cylinder heads, coolant holes for engine blocks, master cylinders, air conditioning compressors, power steering housings, shocks, catalytic converters, bearings, transmission components, carburetors, fuel injectors, and mold making.

Defense

We are proud to work with world leading companies within the Defense Industry to manufacture their tank components, artillery, missiles, combat weaponry, and guidance systems. In a market with rapidly evolving technology, our company prides itself on offering the most advanced tooling to meet the requirements of our customers.

Energy

In an ever-changing market, we are proud to supply our world leading drills for various applications within the Energy Industry. Our drills are being used in nuclear components, windmill technology, and offshore drilling to just name a few. Our engineering and Research and Development specialists are ready to assist you in all your drilling needs.

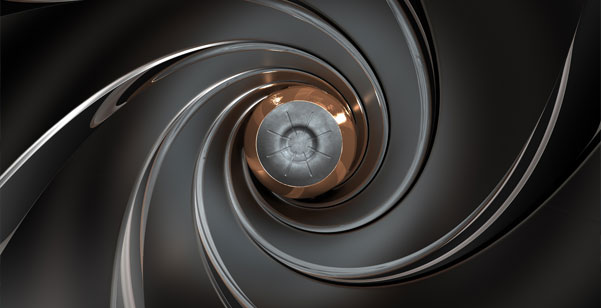

Firearms

We are the global leader in manufacturing precision tooling for the most prominent firearms and barrel manufacturers of the world. Our specialties include deep hole gundrills, rifling buttons, pull bore reamers, hammer forging mandrel, rifle or bore air gauging and accessories. We are highly experienced in SAAMi and CIP specifications in both the commercial and military sectors worldwide.

Heavy Equipment

We provide high quality drills for various large earth moving vehicles including dump trucks, bulldozers, cranes, excavators and mining equipment. Our highly trained team is here to assist our customers through the process from concept, design, manufacturing to delivery.

Medical Industry

Our solid carbide drills are used in various areas of the Medical Industry. One of our specialties includes manufacturing small diameter solid carbide drills which are used when making bone screws that secure numerous types of orthopedic implants. Our precision drills enable the Medical Industry to manufacture the tooling that is used in diagnostic equipment.

Recreational

We provide precision tooling for the multi-faceted and rapidly expanding Recreational Industry. Our drills are being used to manufacture snow mobile, motorcycle, jet ski, and boat engines as well as numerous ATV components.

I was pleasantly surprised to recieve the .123 x 10” coated solid carbide drills today. This was great news as it will allow us to work on a hot project over the weekend. Thanks for getting the rework done so quickly!

Dave H, Fire Arms Industry

Thank you! There are many reasons why I always come back to DME for my gun drills, but customer service is top notch!

Jeremy W, Metal Fabricaiton/Machine Shop

“Thank you for coming here to see our operation, lending your knowledge and expertise, and all the help that you have provided us. I am very excited to continue working with you guys and can’t wait for all the wonderful work you can helpus complete.”

Leo S, Machine Shop Manager

“I could not have gotten this far without you and your team at DMET.”