Nose Geometries

Nose geometries are one of the most important characteristics of successful hole making. There are numerous nose grinds that have been established by end users to critique applications. There are a handful of standard general purpose grinds which are industry standard and have good success for a given material. Modifications are made to these due to material hardness, softness, tinsel strengths, lack of coolant pressure or lubricity, etc.

The N-8, N-4, N-73, and Facet grinds are Industry Standard Grinds while bottom forming, corner radius, full spherical radius, and flat bottom may also be produced in a single pass. Capabilities to blue print specifications may be examined through our engineering department.

All of which can be reproduced in house with a Model “B” sharpening fixture and applicable diamond wheel.

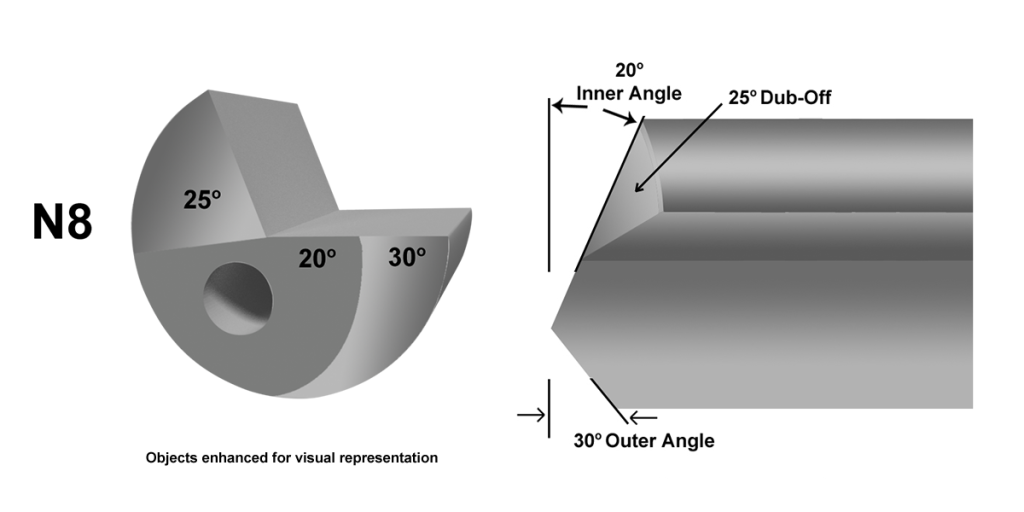

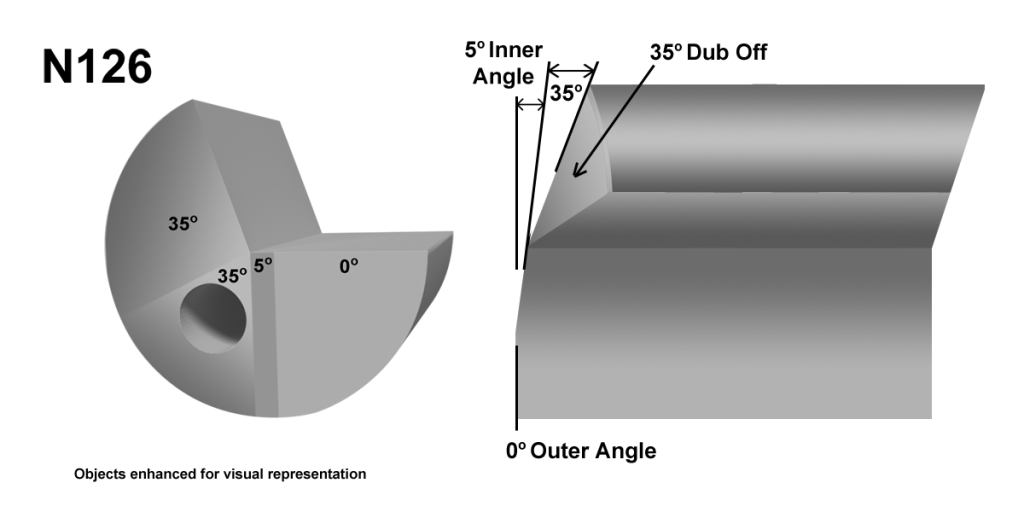

The center design of our gundrills allows for a wide range of Nose Grinds from a full spherical radius to a flat bottom design. The Nose Grind angles are important in achieving optimal results. Angles can be modified to improve the flushing action of the high pressure oil and to improve chip control and removal. Specific grinds have been developed for severe applications such as exit breakouts and interrupted or angular entries. Some of the most popular Nose Grind configurations are shown here.

Bottom Forming

Bottom forming such as a corner radius, full spherical radius, and flat bottom may also be produced in a single pass. Capabilities to blue print specifications may be examined through our engineering department.

Industry Standard Nose Grinds

General purpose stock drill grind for steel, inconel and stainless steel are most often used with stock ‘R1’ O.D. contour.

In aluminum and brass, use this grind with ‘R4’ O.D. contour for best hole finish.

This Nose Grind is used for drilling stacked parts and angular entries. Due to the point’s placement near the center of the drill, this is the strongest gundrill.

This Nose Grind is for applications requiring nearly flat bottoms. It can also be ground for a completely flat bottom or on difficult materials used to qualify bottoms only.

This Nose Grind is for applications requiring nearly flat bottoms. It can also be ground for a completely flat bottom or on difficult materials used to qualify bottoms only.

Facet grinds are preferred on specific applications or when regrind fixtures limit the cam type sharpenings. They can be ground to various slash type angles with good performance, and they allow a greater amount of clearance for coolant to cool the chip at the cutting edge. This grind is standard on most European applications.

Chip Breakers

Chip Breakers are used when chip wrapping occurs. This usually occurs when entering uneven surfaces, intersections, an existing hole, a pilot hole with a cone shape, or with unobtainable feeds or speeds to name a few. Chip Breakers are generally used to break string type chips often attributed to a gummy material or when machines limit the surface footage necessary to generate the heat needed to break a chip. There are two types of Chip Breakers shown below:

|

The Radial Chip Breaker runs down the length of the carbide flat and lasts the life of the tool. |

|

The Standard Chip Breaker runs across the length of the cutting edge and needs to be reproduced after 2-3 re-grinds. |