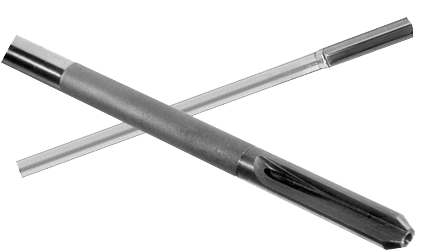

Reamers

Solid carbide tip reamers are available in most diameters and lengths to produce close tolerances, eliminating the need for honing.

Chips ahead and behind of reamers are commonly used to obtain very tight ID bore sizes. Drilling an initial hole that is .015″ – .030″ under the desired finished diameter yields the preferable amount of material to be removed with this type of tool. The result is a hole size to .0002″ in diameter and finishes to 16 RMS or better in a single pass, usually eliminating the need for honing.

TECH SUPPORT

We have a dedicated staff of experts with over 85 years of combined experience to assist the customer with all of their special requirements. At the beginning phase of an engineering project, give us a call to discuss the process sequences required to avoid unnecessary problems in the future. If the customer is experiencing any gundrilling problems or has questions, they should contact our engineering staff for solutions.